Services

METALFAB offers diverse range of integrated services covering the entire project lifecycle in the Engineering and Construction Industry. Our experienced team delivers exceptional results to projects in Oil & Gas, Process, Aluminium, Ports and Engineering Industry.

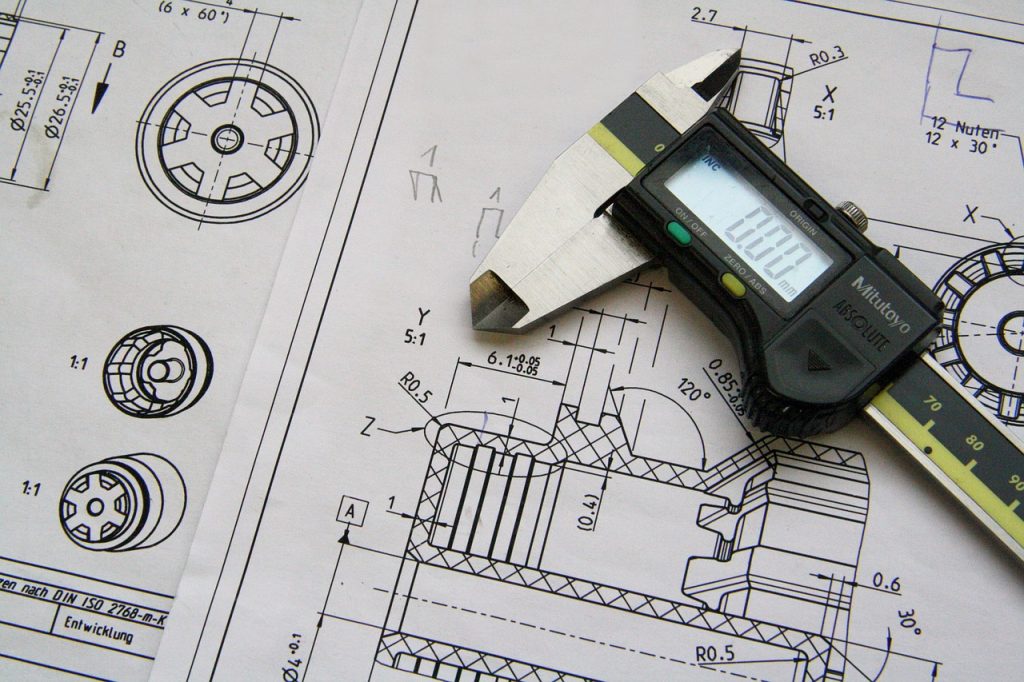

METALFAB specializes in comprehensive Design Engineering and Detailing services, providing meticulous planning and execution for projects of all scales. Our team of skilled professionals utilize advanced tools and methodologies to deliver innovative and customized designs that meet the specific requirements of each project. With a focus on precision and efficiency, we strive to exceed client expectations and deliver solutions that optimize performance and maximize value throughout the project lifecycle.

At METALFAB, Procurement is a fundamental pillar for all our projects and spans the entire spectrum, from diligently sourcing high-quality materials and equipments with trusted suppliers to meticulously managing supply chains and orchestrating logistics. Our stringent quality control measures ensure that all materials meet the highest standards, contributing to project success and client satisfaction. With a focus on excellence, we provide comprehensive procurement solutions tailored to the unique needs of each project, ensuring timely delivery and cost-effectiveness throughout the procurement lifecycle.

METALFAB is a leading provider of Fabrication Services for Piping, Structures, and Storage Tanks, providing customized solutions for diverse projects. With vast expertise and a dedication to excellence, our team delivers high-quality results using advanced technology and best industry practices. Our Fabrication Facility spans across a total area of 58,850 sq m. Within this space, our Shop area covers 10,850 sq m, facilitating efficient operations. Specifically, our Fabrication Area extends over 14,220 sq m, ensuring precision crafting. Additionally, we have designated areas for Blasting (1,950 sq m) and Painting (10,080 sq m). Our Assembly Area, spanning 14,170 sq m, enables seamless integration of various components. Furthermore, we allocate 7,580 sq m for material storage, guaranteeing organized inventory management and timely access to essential resources.

METALFAB demonstrates unwavering dedication to excellence in installing piping systems, structural components, and storage tanks. Our adept team tailors solutions to meet varied project needs, employing innovative methods and industry best practices for smooth, efficient installation. Prioritizing safety and reliability, we handle complex piping networks, sturdy steel structures, and expansive storage facilities with utmost care. Leveraging expertise and meticulous attention to detail, we seamlessly integrate components for dependable operation, ensuring optimal performance and project success.

METALFAB specializes in insulation services for equipment and piping systems, optimizing energy usage and preserving ideal operational environments. Our expert team diligently install insulation materials to boost thermal efficiency, mitigating heat loss and lowering energy usage. By maintaining consistent temperatures, we ensure equipment longevity and operational reliability while also promoting environmental sustainability. Whether for industrial machinery or complex piping networks, our insulation solutions deliver cost savings and performance benefits, reinforcing METALFAB’s commitment to excellence and efficiency in every project.

METALFAB provides an extensive range of maintenance services, including asset management, shutdown support, and technical assistance, aimed at enhancing the reliability and longevity of industrial assets. By executing clients’ planned maintenance requirements, we minimize downtime and improve operational performance.

METALFAB is proficient in providing comprehensive Shutdown Services designed to meet the unique needs of our clients in the Oil & Gas sector. Our experienced team ensures efficient and safe execution of shutdown works, minimizing downtime and maximizing productivity. From meticulous planning and scheduling to precise execution and post-shutdown evaluations, we handle every aspect with precision and expertise. With a focus on quality, safety, and client satisfaction, we are committed to delivering exceptional results on every shutdown project.